Part 1 of our Cryo Cold Chain Management for CGT Series

With a projected rate of 10-20 product approvals per year, the global cell and gene therapy (CGT) industry is rapidly evolving. The clinical pipeline delivers a promise to the patient population with unmet medical needs ranging from oncology to autoimmune diseases and rare genetic conditions. In the US alone, 66 CGT product-indications are expected to be approved by 2032, with an anticipated treatable population exceeding 100,000 patients per year.

Dual Challenges in CGT Manufacturing and Distribution

The cell-based therapies are often called “living drugs”, and it’s the duality of their nature that brings a set of challenges for manufacturing and distribution:

- “Living”: the manufacturing journey starts and ends with living cells being infused or transplanted to the patient

- “Drugs”: these medicinal products are subject to regulation, including Good Manufacturing Practices

These challenges intersect when it comes to cold chain management. The set of processes that ensure temperature-controlled supply chain (storage, transportation, distribution) are critical to avoid temperature fluctuations outside of the defined temperature range. This article discusses the key considerations and best practices for on-site cryogenic cold chain management of cell-based therapies, which are fundamental to the success of these products.

New Wave of Automation

A commonly accepted path to building robust manufacturing strategy, “more automation and closed processing,” promises the market players a way to address various current pain points, such as cost of goods (COGs) and batch-to-batch variability.

As part of a competitive landscape, automation for CGT manufacturing is experiencing a surge, offering solutions aimed at both isolated processes and end-to-end production. A number of companies offer innovative platforms that integrate automation across the production process.

When it comes to processes as critical as the cryogenic cold chain, automation plays a fundamental role. Automated systems for storage, retrieval, controlled freezing, and thawing not only enhance operational efficiency but also ensure the integrity of CGT products.

Workflow Standardization

CGT development and manufacturing facilities process multiple types of cryopreserved cellular material: R&D and PD/AD samples, starting material, QC samples, key-intermediate, and drug products. These materials vary in cell concentration, cell type, cryoprotectant agents (CPAs), collection/filling methods, volumes, and intended use, all of which influence the choice of container systems: cryobags, cryovials, or vials.

Multiproduct CGT manufacturing facilities and CDMOs face the challenge of designing robust workflows that accommodate various primary container types. To address this, it’s crucial to standardize the cryogenic cold chain workflow using a container-agnostic approach. This allows for seamless flexibility between container types and minimizes changeover time, optimizing efficiency across operations.

Critical Quality Attributes and Cold Chain

Quality by Design (QbD) is a well-established approach to product development in the pharmaceutical industry, particularly in terms of the complex manufacturing and validation process for CGT. Since it focuses on deep process understanding and control by evaluating the variables that may impact quality already at early stages of development and product cycle, it is perceived as a good practice and encouraged for application by the regulators.

In QbD, Critical Quality Attributes (CQAs) are defined in the International Conference on Harmonization (ICH) Guideline Q8(R2) as “physical, chemical, biological, or microbiological property or characteristic that should be within an appropriate limit, range, or distribution to ensure the desired product quality.”

Overall, the conditions under which CGT drug products, and their starting and intermediate materials are stored, transported and prepared for use, directly impacts their quality and thus, potential clinical performance of the product.

The table below outlines an assessment of how elements of the cryogenic cold chain impact the safety, purity, potency, content, and overall critical quality attributes (CQAs) of the CGT product.

| CQA Category | Product Attribute | Example of Impact of Cryo Cold Chain |

|---|---|---|

| Safety | Sterility / bacterial endotoxins, mycoplasma | During cryostorage, contact of the cellular material with the liquid phase of LN2 in the tank can lead to loss of container closure integrity and mycoplasma contamination. Water bath as thawing method represents an important contamination risk. |

| General | pH, osmolality | During transportation on dry ice, CO2 migration into the polymer container system, can impact the product pH. |

| Purity/impurities | Dead cells | During cryostorage and handling of frozen cellular material, the transient warming events and transportation above the critical temperature negatively impact the cell recovery, viability, and functionality. |

| Content | Total cell number, cell concentration, viability | During thawing, inadequate or uncontrolled thawing rate or duration leading to overexposure of the cellular material to CPAs, results in cell damage, lowering cell recovery, viability, and functionality. |

Robust In-House Cryo Cold Chain Management

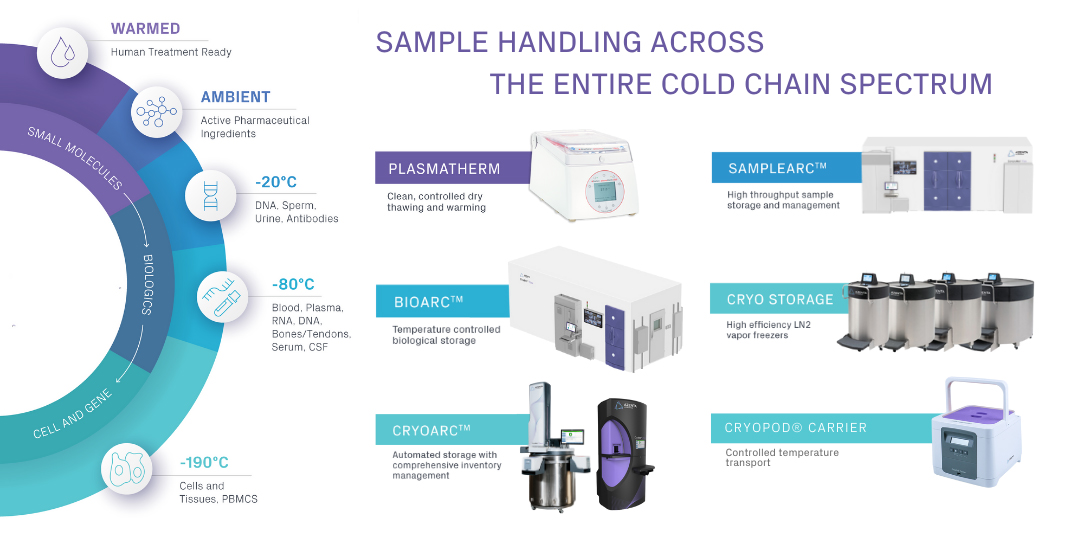

When it comes to the cryogenic cold chain management in the CGT manufacturing facility, it can be categorized into processes such as cell material freezing, storage, in-house transportation, and thawing.

In practice, the purpose of the in-house management of the cryo cold chain is:

- To safely store and handle the cryopreserved cellular material in conditions that stop all enzymatic activity (below water Tg of -135°C) and avoid temperature excursions associated with risks of cell damage

- To rapidly “bring the cells back to life” by thawing in a consistent method, achieving reproducible targeted recovery, viability and functionality

- To avoid risk of contamination or operator’s error

- To efficiently manage the cold chain relevant data and inventory in a compliant way

These objectives can be reached with the introduction of automation and controlled solutions.

Storage

Manual LN2 cryogenic storage units have long been the gold standard. However, this approach might not completely meet the changing requirements of cell and gene therapy (CGT) users, particularly regarding the preservation of high-value starting materials and products. This challenge becomes more pronounced during operational scale-up, as both the number of samples and the number of sites increase.

Robustness of storage and reproducibility of retrieval can be achieved by introducing automation, simultaneously enabling:

- Minimization of the transient warming of the non-targeted samples

- Avoiding errors associated with operator-dependent sample identification and manipulation

- Strong inventory management (even across sites) and 21 CFR Part11 compliance

The CryoArc™ Pico LN2-Based Automated Storage System by Azenta Life Sciences was designed for this purpose, and safeguards high-value biological samples used in clinical and commercial CGT manufacturing.

Frozen Material In-House Transportation

Uncontrolled on-site transportation methods for cryopreserved materials from storage to the point of use introduce additional variability and require significant validation efforts. Common practices like storing on dry ice can increase the rate at which samples warm, especially after transient warming events. Transporting cells stored in LN2 on dry ice actually warms them to -80°C very fast. Read more about Thermal Protection in this White Paper.

Many biological samples contained inside cryoboxes are stored in LN2 vapor-phase freezers at temperatures below -150°C to preserve their viability. The underlying assumption is that biological samples show highly reduced degradation and metabolic activity while below Tg (the glass transition temperature). However, every time a cryobox is manipulated or temporarily removed from a LN2 freezer the enclosed samples experience thermal excursions. They could be harmed by inadvertently crossing the Tg threshold or by exposure to excessive thermal excursions.

Devices that control and log temperature, maintaining at least -135°C during hold times while moving between storage to the point of use within the facility, enable the design of robust material flows. Additionally, color-coding these devices offers a practical solution for staff to quickly visually identify and differentiate between various categories of samples being handled in the facility.

One example of this is the Azenta Life Sciences CryoPod® Carrier, a device designed to support the efficient flow of cryopreserved materials in GMP facilities.

Thawing

In R&D, water baths are commonly used for thawing of cellular material due to their affordability, flexibility, and gentle handling of cellular material. However, further down the development timeline, transitioning to dry thawing solutions is necessary for GMP compliance.

The key considerations related to thawing, having the impact on the CQAs are:

- Thawing rates / thawing temperature

- Duration of thawing

- Avoiding of thermal gradients

Controlled dry thawing devices provide a compliant, reproducible process comparable to traditional water baths. Thawing devices that support multiple container types add flexibility to the process and help reduce qualification costs.

Minimizing thermal gradients—such as through consistent agitation—becomes increasingly important when working with larger volumes. In GMP manufacturing environments, dry thawing devices must also meet cleanroom installation standards to ensure compliance.

The Barkey plasmatherm C&G from Azenta Life Sciences is a flexible dry-thawing device, which has been used for years by both commercial CGT manufacturing and administration.

In-House Sample and Data Management: Toward Pharma 4.0

As the CGT industry progresses, effective in-house sample and data management become critical components of cryogenic cold chain management. Numerous players are undergoing digital transformation and introducing Pharma 4.0 principles, which focus on integrating advanced digital technologies into manufacturing and can significantly enhance these processes, ensuring strong alignment with QbD principles.

Sample Management

Efficient sample management involves tracking and controlling samples throughout the manufacturing process. Implementing automated systems for sample tracking ensures accurate data collection, reduces human error, and enhances traceability. Software and automated systems for sample tracking, such as barcoding and RFID tagging, ensure accurate data collection, reduce human error, and enhance traceability. These systems streamline the identification, retrieval, and inventory management of samples, ensuring compliance with regulatory requirements and maintaining the CQAs.

Data Management

Implementing electronic batch records (EBRs) and laboratory information management systems (LIMS) allows for real-time data collection, monitoring, and analysis. These systems provide a comprehensive overview of the CGT manufacturing process, enabling proactive decision-making and continuous improvement.

Pharma 4.0 Integration

Pharma 4.0 represents the next industrial revolution in pharmaceuticals, characterized by the integration of digital technologies, automation, and data analytics. In the context of cryo cold chain at CGT facility, Pharma 4.0 involves:

- IoT and Connectivity: Implementing IoT devices for real-time monitoring of cryogenic storage conditions, ensuring optimal temperature control and early detection of potential issues.

- Advanced Analytics: Utilizing big data analytics and machine learning to predict and mitigate risks, optimize processes, and enhance product quality. These analytics tools can identify trends and deviations in CPPs that could impact CQAs, enabling preemptive corrective actions.

- Digital Twins: Creating digital replicas of manufacturing processes to simulate and optimize workflows, identify bottlenecks, and improve efficiency, understanding the impact of process changes on the CPPs.

- Blockchain: Leveraging blockchain technology for secure and transparent data sharing, ensuring the integrity and traceability of the supply chain.

Learn more about how informatics and sample management LIMS solutions support efficient storage of critical CGT samples.

Conclusion

Effective in-house cryogenic cold chain management is vital for preserving the integrity and quality of CGT products. By utilizing automation and controlled solutions for cryostorage, in-house transportation, and thawing—along with standardized workflows and robust data management—manufacturers can safeguard the safety, purity, potency, content, and critical quality attributes (CQAs) of CGT products, ultimately ensuring successful clinical outcomes.

Discover cutting edge solutions for cryo storage, transport, and thawing needs from Azenta Life Sciences.

Selecting Cryogenic Storage Solutions

Download our guide to selecting cryogenic storage solutions.

About the Author

Olga Bukatova

Olga Bukatova is an Associate Director Business Development, CGT, at Azenta Life Sciences. With a decade-long commitment to advancing GMP manufacturing technologies for Cell and Gene Therapies, Olga Bukatova’s expertise spans critical domains, including process automation, cryopreservation and thawing, isolator technologies, and aseptic fill and finish. As a member of the ISCT cold chain working group, she keeps on addressing the multifaceted challenges within the CGT landscape.