Part 2 of our A Practical Guide to Planning a Cryogenic Storage Facility Series

In our previous post, we covered several key considerations for selecting the appropriate space and equipment when designing your cryogenic storage facility. In this post, we will highlight how to ensure the safety of your facility.

Did you know that a proper LN2 monitoring system can mean the difference between life and death? Given that nitrogen is lighter than air, it can rapidly displace oxygen in a room, which can lead to asphyxiation. Below are six safety factors you should consider to avoid these safety concerns:

Oxygen Monitoring

Oxygen monitors need to be in place to notify staff of dangerous levels. These systems should be in areas that are exposed to LN2, clearly indicating the nature of the alert and the associated risk. In most systems, there are multiple notification settings for various oxygen levels to indicate slightly out-of-range conditions versus significantly out-of-range conditions. However, if your oxygen monitor has only one alarm setting, it should be set at 19.5% oxygen, the point at which staff need to be evacuated immediately.

Curved Mirrors and Camera

Having curved mirrors and cameras installed in your LN2 facility makes it easier to perform visual inspections of LN2 storage units and identify staff during an emergency. When positioned correctly, mirrors and cameras can help observe if anyone has collapsed in the facility.

Specimen Integrity Monitoring

Monitoring systems are key to preventing specimen loss. Having a specimen integrity monitoring system that will alert staff of urgent issues and provide insight into storage conditions, such as temperature and functionality, is necessary. Make sure you have redundant sources of monitoring in place, both human and electronic, for added security.

Temperature Monitoring

LN2 storage units need to have continuous temperature monitoring by a certified and traceable thermometer. Even when specimens are completely submerged, monitoring can provide reassurance that a proper temperature is maintained if the LN2 level falls out of range. In addition, you may want to place a redundant thermometer at the highest level of where the specimens are stored.

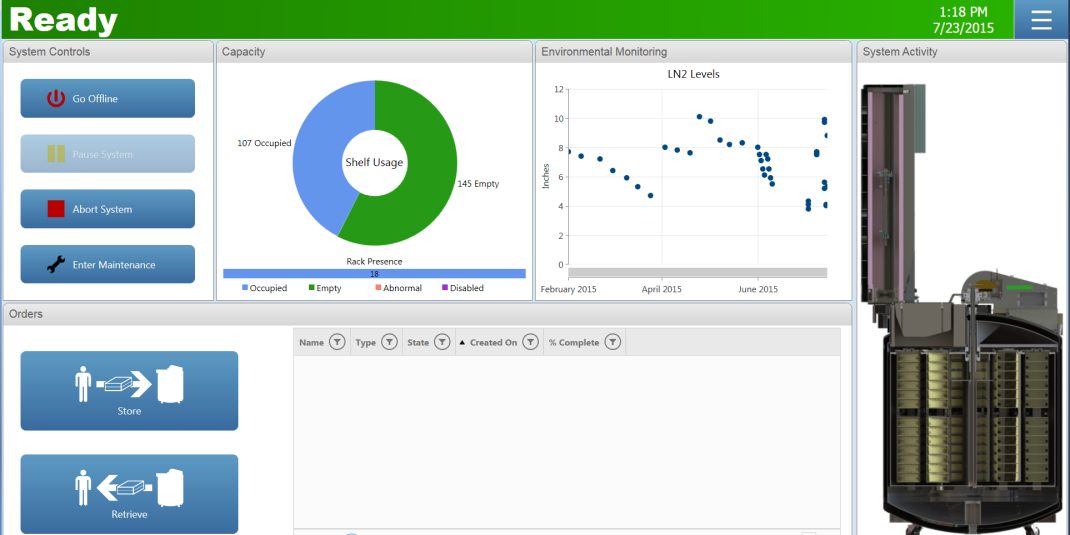

LN2 Level Monitoring

The LN2 level in each storage unit should be monitored and recorded manually to the nearest quarter inch (0.25 inch or 6 mm). When performed manually, a plastic or metal yard stick is recommended. Do not use a hollow tube, as LN2 can rapidly shoot out of the top once inserted into the cold liquid nitrogen. When using an electronic component to measure LN2, the electronic level should be monitored and recorded. The manually measured LN2 level should be compared to the electronic level within a predefined acceptable range. If out of range, calibrate the electronic LN2 level to match the manually measured level.

LN2 Consumption Monitoring

LN2 consumption should be measured and recorded manually (for manual-fill LN2 storage units) and electronically (for auto-fill LN2 storage units). For manual-fill LN2 storage units, wireless remote, weight-based monitoring systems provide continuous measurements that can be precisely correlated to LN2 levels and used to determine evaporation rates. On auto-fill LN2 storage units, the electronic monitoring system provides this information. Since auto-fill LN2 storage units fill on an “as needed” basis, it can be difficult to determine LN2 usage manually. A clear acceptable range of consumption with a calculated standard deviation should be included, as identified by the manufacturer’s guidelines and in accordance with the facility’s average usage.

Summary

A well-monitored and safe LN2 facility is critical to the long-term success of your cryogenic storage. By putting in place a comprehensive monitoring system, you can have peace of mind that your staff and specimens are properly protected.

Interested in learning more about cryogenic storage and how to set up your own facility? Download our full guide.

Explore more in the A Practical Guide to Planning a Cryogenic Storage Facility Series

References

- Best Practices: Recommendations for Repositories (4th ed), Addendum 1: Liquid Nitrogen-Based Cryogenic Storage of Specimens. ISBER. 2019. https://www.isber.org/page/BP_English_4thEd-Addendum