Like many industries, the global research landscape is increasingly shaped by the push to adopt more sustainable practices. Energy-efficient and carbon-neutral operations are leading drivers in the future of sustainable sample storage in the biotech and pharma industries. This shift is particularly significant for companies in Europe and the UK, where new regulatory mandates require substantial reductions in carbon emissions by 2030.

For companies faced with stringent new sustainability goals, one key area for consideration lies in the optimization of cold-storage systems. The traditional manual and front-opening freezers used in biobanking, sample warehousing, and the production of diagnostics and biological therapeutics play a substantial role in both energy consumption and operational expenses, impacting footprint space as well. By adopting more efficient freezer management practices and new technologies, companies can not only decrease their carbon footprint but also realize substantial cost savings. The question is, how can this be achieved while mitigating costly disruptions and maintaining operational efficiency?

The answer lies in the strategic optimization of cold storage systems — a significant energy consumer in biobanking. Here, we outline a series of key strategies that can enhance energy efficiency, reduce costs, and foster a culture of sustainability.

Regular Freezer Maintenance

Maintaining your freezers is never a bad idea. Without routine upkeep, manual freezers can develop issues (like build-up and debris) that prevent them from operating at maximum efficiency. When these issues develop, your freezer will end up requiring greater energy expenditure to maintain temperatures, wasting power, costing you money, and potentially compromising samples. Implementing a robust freezer maintenance program can extend the life expectancy of your freezers, ensuring they continue to run efficiently and sustainably. Additionally, prolonging and potentially eliminating the need for freezer replacement means higher savings, and less material waste for the environment.

Need help with your automated freezer maintenance? Check out Azenta Support Options.

Optimized Inventory Management

A well-maintained inventory management system allows for samples to be easily tracked, saving time and increasing visibility. By reviewing current inventory and rearranging or discarding infrequently accessed samples, you can free up space for active studies, further reducing the need for physical storage. A digital management system provides an additional level of security and compliance, with audit trails that ensure your samples maintain integrity throughout their chain of custody. Furthermore, a cloud-based system helps you consolidate your samples and locate them more efficiently.

Learn more about the Azenta Limfinity® sample management system.

Embrace Automation and Advanced Technologies

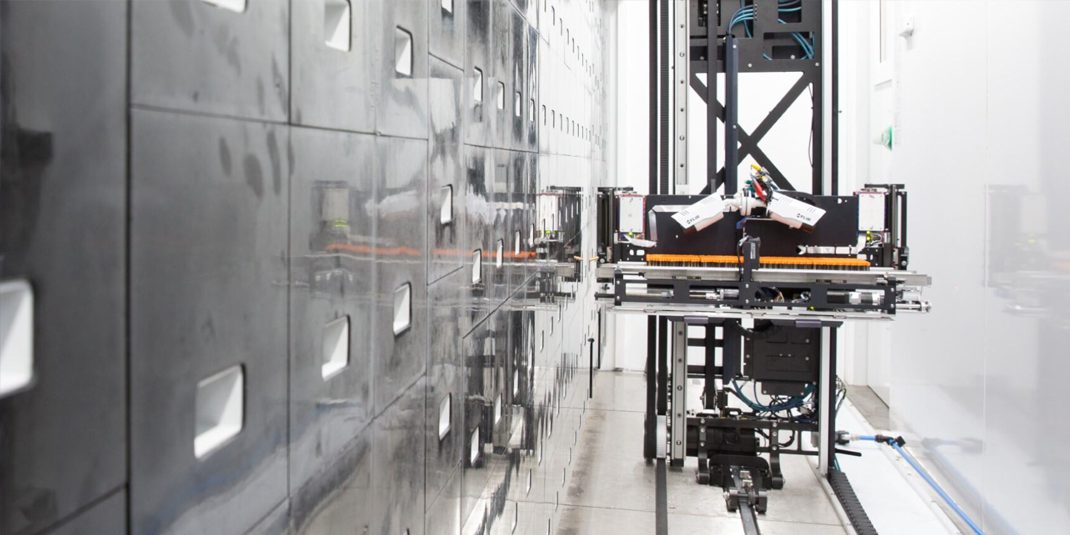

It may not seem like much, but each time you open the freezer door you let out precious cold air, meaning the freezer must work harder to cool back down. The longer you spend searching for samples, the more energy is wasted. Automation can streamline workflows, making the process of finding and accessing samples faster and more efficient. With picker modules attached to robotic arms inside a fully enclosed freezer system, innocent samples are not exposed to ambient temperatures during selection, and you waste less refrigeration energy during the process. That’s why automation not only provides workflow efficiency benefits, but also helps support a more sustainable future.

Learn more about automated sample storage solutions.

Cultivate a Culture of Sustainability

Small actions, such as turning off unused equipment or lights, and minimizing the opening of freezers, can significantly reduce energy consumption. By fostering a culture of sustainability within the organization and establishing material management best practices, these strategies can become seamlessly integrated into daily workflows. It’s also important to make sure your practices have fail-safes to ensure the security of your samples. The last thing you want is for a well-meaning employee to unplug a power cord and shut down a freezer, ruining your high-value collection. Automation helps prevent these types of situations, while consolidating the picking routines and streamlining your workflows as well.

Take a deeper dive into sustainable refrigerators and freezers.

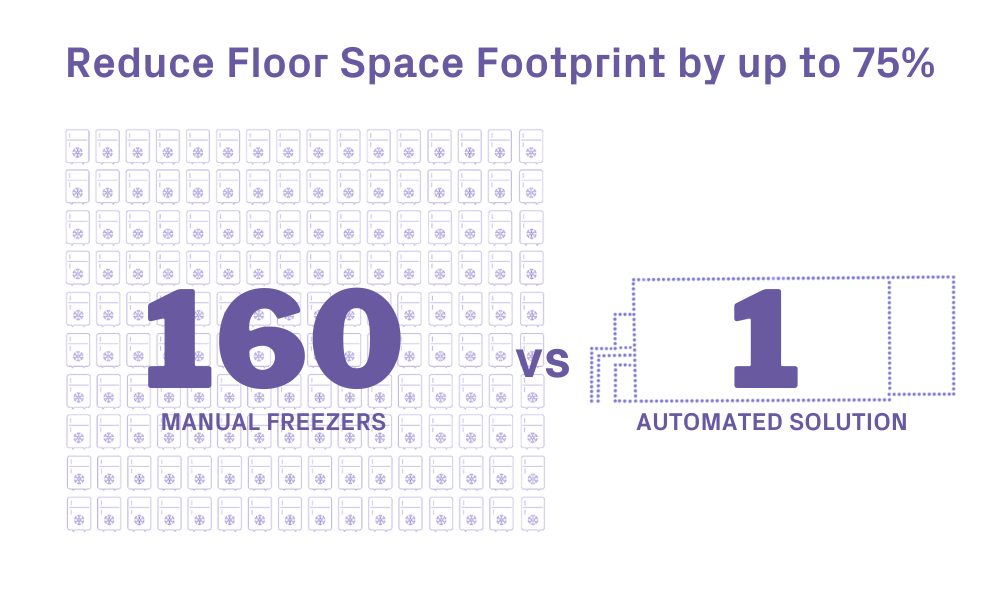

Increase Storage Density

A critical step towards reducing your carbon footprint is maximizing storage density. Proper freezer consolidation can cut down your cold storage footprint by 40-80%. The Azenta BioArc™ line of automated biostorage systems optimize freezer density, and compared to manual freezers, take up much less space for the same amount of storage. A new Azenta system, coming soon, takes freezer density to new heights. But what does this mean for your energy consumption? It’s simple — compact storage equals less energy expenditure, thus lowering your carbon footprint.

Something Big Is Here

At Azenta, we take optimizing cold storage seriously. In February 2024, we unveiled a new solution focused on the sustainability challenge. This state-of-the-art biostorage solution:

- Up to 272% higher tube density per surface area compared to manual freezers

- Uses up to 85% less power than equivalent manual storage options*

- Will reduce freezer floor space requirements by up to 75%*

These innovations are expected to result in:

- Up to 86% lower electric costs*

- Potential savings of more than $150K per year*

- Zero global warming potential

The BioArc™ Ultra can replace the equivalent of up to 160 manual freezers*, presenting an unparalleled opportunity for companies to meet the new EU and UK carbon emissions reduction mandates. The shift to more sustainable cold storage practices is not just an environmental necessity; it’s a strategic move that will drive operational efficiency and cost savings.

Moving towards a sustainable future in sample storage involves implementing energy-efficient practices, leveraging advanced technologies, and promoting an environmentally focused culture. Azenta is committed to supporting you at every step of this journey, as we continue to bring forth novel solutions that combine high performance with sustainable design. Together, we can reduce our carbon footprint, and embrace a more sustainable tomorrow.

Find out more about the BioArc™ Ultra High-Density -80°C Automated Sample Storage System.

*Based on Azenta’s own calculations