Sample inventory management is a continuous process that supports the integrity of your data and research. Yet with samples and critical reagents added over time, sprawling inventories can strain valuable time, energy, and resources.

An objective inventory review, conducted by better storage management experts, can help to optimize your sample and material storage and sustain this efficiency over time. The benefits are multi-faceted and can support your organization’s overarching goals.

Here, we define and outline general steps in a comprehensive cold storage assessment.

The Sample Inventory Struggle is Real

A cold, hard truth in sample inventory management is that sample and critical reagent collections often expand faster than expected. As quantities quickly outpace available storage space, the instinct may be to procure more liquid nitrogen (LN2) vapor storage (also called cryogenic freezers), ultra-low temperature (ULT) or standard freezers, and refrigerators.

This approach consumes valuable laboratory budget and space. It can also amplify cold storage sprawl. Even more time needed to find materials of interest can distract researchers from their high-value tasks.

Fortunately, there’s a more impactful and sustainable approach to optimized sample inventory management.

Real Change Begins with a Better Storage Management Assessment

Better storage management is a comprehensive and well-organized foundation to enable efficient cold chain sample organization and quantifiable benefits. Here, efficiency experts specializing in cold chain sample and material storage collaborate with laboratories to evaluate every aspect of their current, unique sample inventory management landscape.

External Evaluation: General Maintenance and Environmental Factors

A survey of the sample storage room’s environmental parameters can help to determine if cold storage units (CSUs) are working harder than normal to maintain internal temperatures. Overexertion can shorten the lifespan of compressors and other CSU components and can also increase energy consumption and utility costs.

Ambient room temperatures must be between 60°F – 90°F for ULT freezers to operate normally. Room temperatures outside of this range may cause immediate freezer failure. On top of this, high room humidity levels can lead to moisture buildup and encourage microorganism growth.

The experts also look for dust and debris that can cover freezer coils or clog filters. Buildup like this can strain the cooling system, which may lead to temperature fluctuations and increased energy use.

Small details, like inspecting CSU door hinge alignment and door handle function, can help to uncover potential performance issues.

CSU placement is an important but often overlooked factor. If CSUs are located too close to walls, equipment, or each other, airflow is restricted which allows heat (and energy costs) to build up. Even proximity to a room’s air vent blowing hot or cold air can force one CSU to work harder than another.

Internal Evaluation: Integrity and Organization

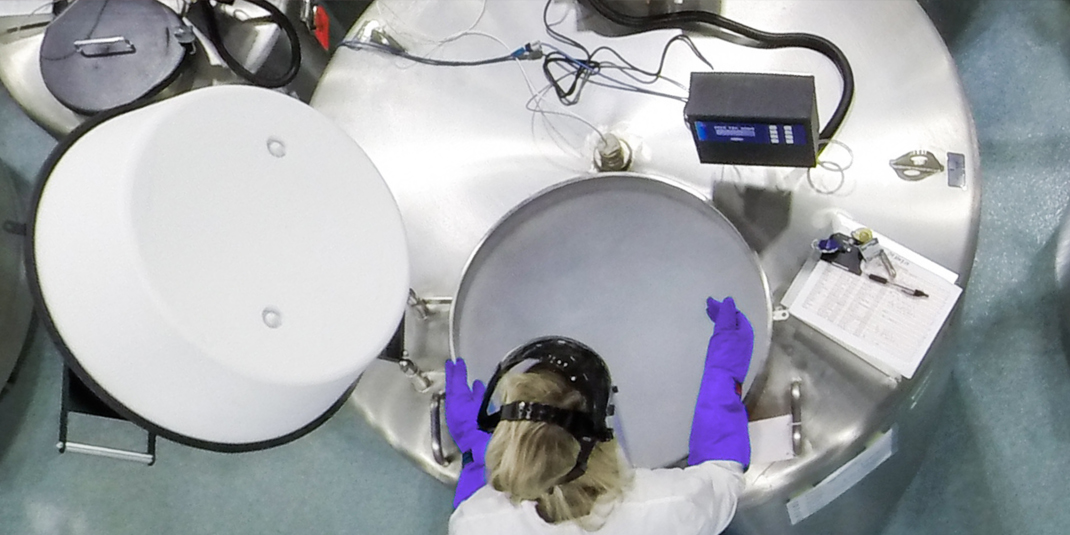

A physical condition check ensures proper functionality and performance of each LN2, ULT and standard freezer, and refrigerator.

The efficiency experts will look at the condition of sealing gaskets on CSU outer doors and sub-doors to ensure that they are undamaged and intact. They’ll also check for any ice build-up. Air leaks from improperly sealed doors and sub-doors may threaten sample integrity, promote frost build-up inside the unit, and drive up energy consumption.

The detailed assessment takes note of any frost buildup that can block internal air convection and take up valuable space on shelves and racks. Consequences of this snowy buildup are temperature variations that can impact sample integrity and unused opportunity to densify material organization.

Along those same lines, proper material organization is assessed for more benefits beyond optimized storage capacity. A logical sample organization strategy ensures that horizontal and vertical space in each CSU is maximized. An estimate of space utilization is captured to determine if there is opportunity to reduce the total number of units in operation.

Excellent organization makes it easier and faster for researchers to find their samples or critical materials of interest. Lower access frequency means less risk that innocent samples are exposed to room conditions and less likelihood that samples are misplaced in the future.

This organization is also essential if a unit fails and its contents must be transferred to a properly functioning CSU. Without properly labeled racking or bins to hold the inventory, the time needed to transfer materials to a backup unit greatly increases, and it is more difficult to keep order. This means that it may be harder to find transferred materials in the new unit.

Stakeholder Evaluation: Workflows and Pain Points

People are just as important to the better storage management assessment as hardware and samples. The storage management experts will conduct surveys with all stakeholders at the facility to get a sense of how cold storage materials are used and managed.

This survey reviews the number of impacted labs and buildings, how many CSUs are in use, what types of materials are stored, and how often the materials are accessed and transported. It also examines who maintains the equipment and what cold chain tracking systems, if any, are in place to manage the inventory.

Deep dives focus on how effective and diverse the systems are, areas to improve, how information and resources are shared among colleagues, and where new efficiencies can make the biggest impact.

These aggregated insights help to ensure that recommendations to resolve pain points and improve efficiency are aligned with the facility’s overarching goals.

The Final Assessment Report and Change Management

A comprehensive report summarizes key findings from the external, internal, and stakeholder evaluations. Actionable recommendations may include:

- Implementing tools for better tracking and organization

- Creating data standards that can be used throughout the organization

- Consolidating existing materials to maximize space utilization

- Rationalizing and dispositioning outdated, unidentifiable, or duplicate samples

- Grouping stored samples by frequency of use

- Creating a centralized storage area within the facility or nearby proximity for same day delivery

- Strengthening hardware maintenance protocols

- Developing guidelines and/or policies for cold storage use

- Creating a change management program to support the changes that will be implemented

All recommendations aim to improve cold storage practices so that samples remain protected, researchers save time, and the facility meets cost reduction and environmental goals.

Turning sample management recommendations into tangible actions, and sustaining these actions over time, can be its own challenge. Here again, sample management experts can help by eliminating barriers to change.

In cooperation with the facility teams, these experts lead the implementation project. With convenience and efficiency, they apply the recommended changes, work with and train impacted teams across the facility, implement tools like inventory management software or a laboratory information management system (LIMS), and quantify metrics to gauge progress towards the desired goals.

Bring Clarity and Control to Your Sample Inventory Management

A multi-dimensional better storage management assessment, paired with clear and actionable recommendations, can help any facility to work more efficiently. Under the guidance of storage management experts, benefits of saving time, lowering costs, reducing environmental impacts, and even enhancing communication can be sustained far into the future to propel success.