Natural disasters, extended power outages, and equipment failures can destroy priceless biomaterial. Disaster recovery plans that include multiple backup systems are crucial for all biostorage and research facilities. In disaster scenarios, the choice of freezer type can make the difference between complete sample loss and maintaining biomaterial integrity.

Using Freezers to Protect Biomaterials from Unexpected Events

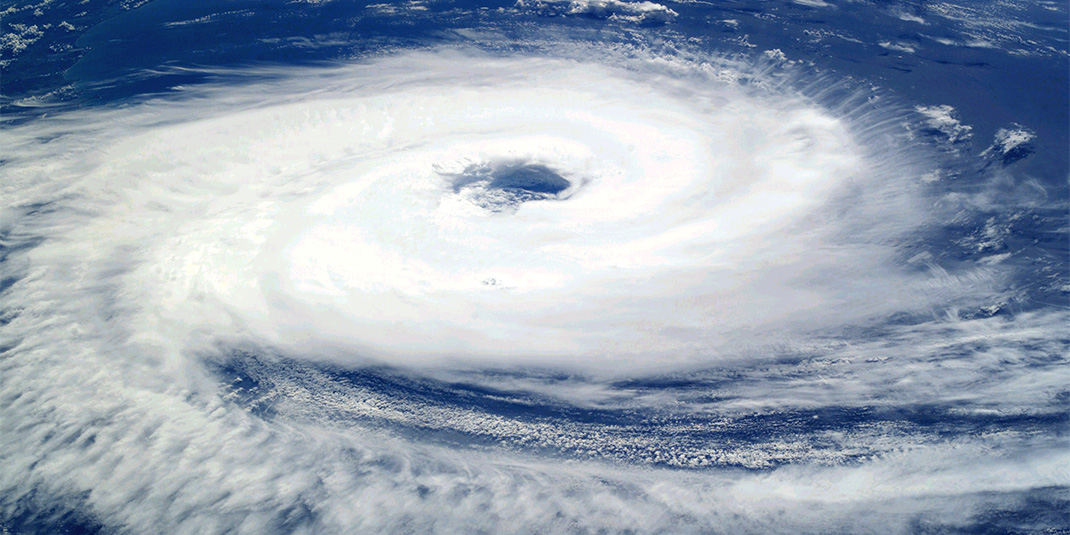

In the past, natural disasters such as hurricane Katrina (2005) and superstorm Sandy (2012) have caused severe damage to valuable collections of biomaterial. Inadvertent equipment failures have also jeopardized priceless tissue collections, exemplified by the dramatic loss of 1/3 of the world’s largest collection of autistic brain samples after freezer failure. These and similar unfortunate events have reshaped our thinking about disaster recovery and the need to protect stored biomaterial from events beyond our control.

Plans for risk mitigation and disaster recovery are now recognized to be an essential feature in biobanks, biotech companies, and core facilities at universities. However, one choice rarely considered in the context of disaster recovery is the selection of the type of freezers used for storage of cryogenic biomaterial. Kathi Shea, Senior Directory of Repository Innovation at Azenta Life Sciences, makes a compelling argument in favor of storage technologies based on liquid nitrogen.

“Mechanically cooled freezers require a dry environment for their compressors, and power 24/7. But liquid nitrogen cooled freezers can operate for extended periods of time without electricity,” she explains.

She points out that cryogenic storage in LN2 tanks has some unique disaster mitigation benefits that other cold storage technologies cannot offer.

“In a power outage, full mechanical freezers will warm at a rate of up to 10°C per hour,” she says, “Samples that are stored in an LN2 tank are much safer, as these tanks will maintain temperature for upwards of 20 days for your biological products.”

This extra time might make all the difference in disaster response scenarios. Emergency rescue operations, especially when properly planned, will (in all likelihood) be concluded within a few days. Biomaterial collections stored in LN2-based units, if properly maintained and regularly filled with liquid nitrogen, will not suffer from temperature fluctuations or transient warming events (TWEs). These TWEs are known to cause a substantial decrease in post-thaw viability and functionality of stem cells.

Automated Cryostorage Maintains Cryogenic Conditions During Emergencies

In disaster recovery situations, as well as for everyday operations, Azenta Life Sciences offers an ideal solution to cryogenic biomaterial storage with the automated CryoArc™ System.

These systems are advantageous in disaster recovery, because it is LN2-based and can hold the temperature for up to three weeks or more after LN2 replenishment. In the event of a natural disaster or an extended power outage, the biological products that are in the unit are completely safe and stored at temperatures lower than the glass transition temperature of water (approximately -135°C), conditions under which all biological activity and diffusion are thought to cease.

The system is perfect for everyday operations because it minimizes the persistent problem of transient warming events for innocent samples, such as samples that happen to reside close to a sample marked for retrieval from storage.

In fact, LN2 tanks, entire racks are usually removed by hand from the cold environment to obtain a single sample. In the automated CryoArc -190°C System, only the relevant biomaterial box is retrieved.

Boost Your Overall Risk Mitigation Plan with Advanced Cryofreezers

When formulating disaster recovery policies, installation of an automated LN2-based freezer system would be a perfect choice for biobanks and biorepositories as well as core facilities and biological labs that need to store biosamples at cryogenic temperatures.

As Kathi Shea points out, “The CryoArc -190°C System retains the benefits of a manual LN2 freezer, but also provides improved protection and efficiency with the use of sample automation. By having the automation, we provide consistency in sample handling. We minimize sample warmings, keeping all samples below the glass transition temperature and protecting the innocents.”

Naturally, planning for disaster recovery does not stop with the choice of the appropriate and best biostorage technology. Such plans should also include training sessions for key personnel and contingency plans for relocation of the entire lab.